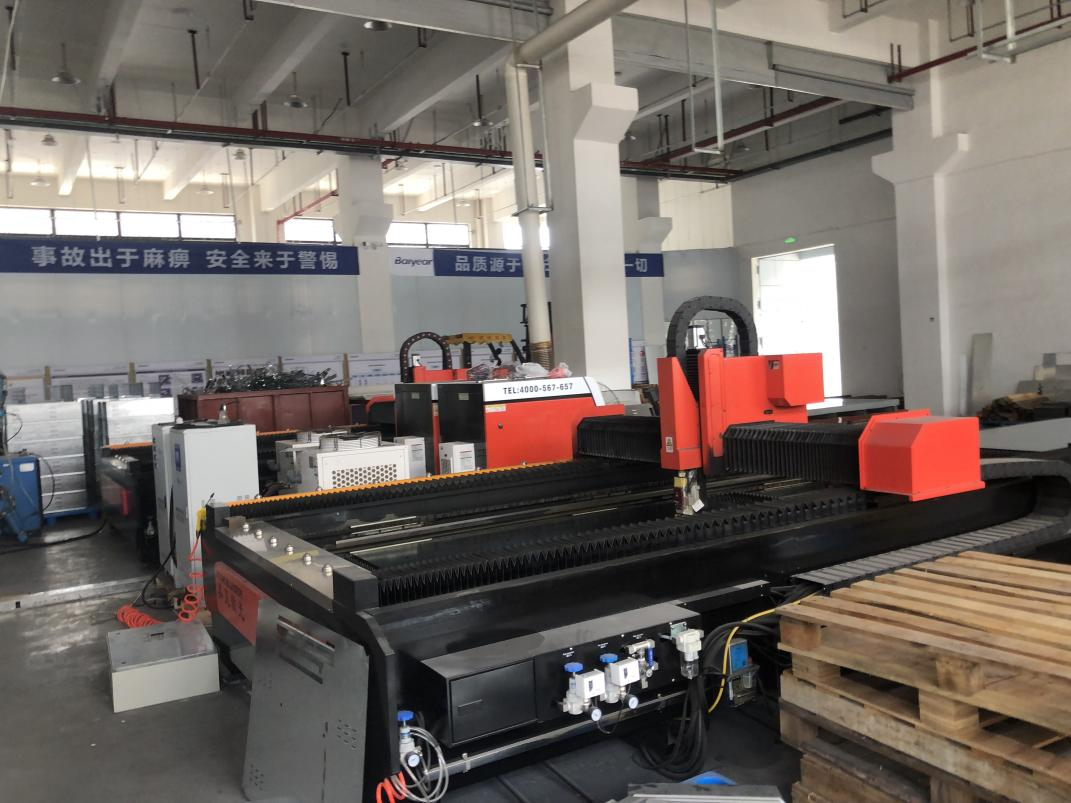

Wolemba Andy wochokera ku fakitale ya Baiyear

Idasinthidwa Novembala 1, 2022

Chitsulo chachitsulo sichinakhale ndi tanthauzo lathunthu.Malinga ndi tanthauzo mu nyuzipepala yakunja akatswiri, angatanthauzidwe monga: Mapepala zitsulo ndi mabuku ozizira ntchito ndondomeko kwa mbale woonda zitsulo (nthawi zambiri pansi 6mm), kuphatikizapo kumeta ubweya, kukhomerera / kudula/kuphatikiza, pindani, kuwotcherera, riveting, splicing , kupanga (monga thupi la galimoto), etc. Chinthu chake chodabwitsa ndi chakuti makulidwe a gawo lomwelo ndilofanana.

Kudula zitsulo ndi njira yofunika kwambiri popanga zinthu zachitsulo.Zimaphatikizapo kudula miyambo, blanking, kupinda kupanga ndi njira zina ndi magawo ndondomeko, komanso zosiyanasiyana ozizira mitundu kufa nyumba ndi magawo ndondomeko, zipangizo zosiyanasiyana ntchito mfundo ndi njira opaleshoni, komanso luso latsopano stamping ndi luso latsopano .

Kwa gawo lililonse lachitsulo lachitsulo, lili ndi njira inayake yopangira, yomwe imatchedwa njira yaukadaulo.Ndi kusiyana kwa mapangidwe a mapepala azitsulo, njira zamakono zingakhale zosiyana, koma chiwerengero sichidutsa mfundo zotsatirazi.

1. Pangani ndi kujambula gawo lojambula la zigawo zake zachitsulo, zomwe zimadziwikanso kuti mawonedwe atatu.Ntchito yake ndi kufotokoza mawonekedwe a zigawo zake zachitsulo pogwiritsa ntchito zojambula.

2. Jambulani chithunzi chosafutukuka.Ndiko kuti, tsegulani gawo lokhala ndi dongosolo lovuta kukhala gawo lathyathyathya.

3. Kusatchula kanthu.Pali njira zambiri zochotsera, makamaka m'njira zotsatirazi:

a.Makina ometa ubweya.Ndiko kugwiritsa ntchito makina ometa kuti adule mawonekedwe, kutalika ndi m'lifupi mwazojambulazo.Ngati pali kukhomerera ndi kudula pamakona, ndiye tembenuzirani makina okhomerera kuti aphatikize nkhonya yakufa ndi kudula pamakona kuti apange.

b.nkhonya popanda kanthu.Ndiko kugwiritsira ntchito nkhonya nkhonya gawo lathyathyathya pambuyo poti mbali zake zavumbulutsidwa pa mbale mu sitepe imodzi kapena zingapo.Iwo ali ndi ubwino yochepa munthu maola, dzuwa mkulu, ndipo akhoza kuchepetsa processing ndalama.

c.NC CNC ikusowa.Pamene NC blanking, sitepe yoyamba ndi kulemba CNC Machining pulogalamu.Ndiko kugwiritsa ntchito pulogalamu yamapulogalamu kulemba chojambula chokulitsa kukhala pulogalamu yomwe ingazindikiridwe ndi makina opangira makina a NC CNC.Lolani kuti itsatire mapulogalamuwa pang'onopang'ono pachitsulo chachitsulo Pamwamba, tulutsani mawonekedwe a magawo ake athyathyathya.

d.Kudula kwa laser.Amagwiritsa ntchito njira yodulira laser kuti adulire mawonekedwe ake athyathyathya pa mbale yachitsulo.

4. Kuwombera ndi kugogoda.Kubowola kumatchedwanso kubowola dzenje, komwe ndiko kujambula dzenje lalikulu pang'ono pa dzenje laling'ono, kenako ndikubowola.Izi zitha kuwonjezera mphamvu zake ndikupewa kuterera.Nthawi zambiri ntchito pepala zitsulo processing ndi ndi woonda mbale makulidwe.Pamene makulidwe a mbale ndi aakulu, monga makulidwe a mbale pamwamba pa 2.0, 2.5, ndi zina zotero, tikhoza kugunda molunjika popanda flanging.

5. Punch processing.Nthawi zambiri, kukhomerera ndi kudula pamakona, kukhomerera kulibe kanthu, kukhomerera chiboliboli chopingasa, kukhomerera ndi kung'amba, kukhomerera ndi njira zina zowongolera zimagwiritsidwa ntchito kukwaniritsa cholinga.Kukonza kumafuna nkhungu zofananira kuti amalize ntchitoyi.Palinso nkhungu zokhomerera ziboliboli zokhomerera, komanso zong'ambika zomwe zimapanga nkhonya ndi kung'amba.

6. Pressure riveting.Pankhani ya fakitale yathu, ma riveting studs, ma riveting mtedza, pressure riveting screws, etc.Amapangidwa ndi zigawo zachitsulo.

7. Kupinda.Kupinda ndikupinda zigawo za 2D zathyathyathya kukhala magawo a 3D.Kukonzekera kwake kumafuna makina opindika ndi kufa kofananira kuti amalize ntchitoyi.Ilinso ndi ndondomeko yopindika.Khola loyamba lomwe silimasokoneza litulutsa khola lomaliza lomwe limasokoneza.

8. Kuwotcherera.Kuwotcherera ndi kuwotcherera mbali zingapo pamodzi kuti akwaniritse cholinga chokonza kapena kuwotcherera mbali imodzi ya gawo limodzi kuti awonjezere mphamvu zake.Njira zogwirira ntchito zimaphatikizapo izi: kuwotcherera kwa mpweya wa CO2, kuwotcherera kwa argon arc, kuwotcherera kwa malo, kuwotcherera kwa robot, ndi zina zambiri.Nthawi zambiri, kuwotcherera kwa mpweya wa CO2 kumagwiritsidwa ntchito powotcherera mbale yachitsulo;kuwotcherera argon arc ntchito kuwotcherera mbale aluminiyamu;kuwotcherera kwa robot kumagwiritsidwa ntchito makamaka pazinthu zakuthupi Zimagwiritsidwa ntchito pamene mbali zake ndi zazikulu ndipo msoko wowotcherera ndi wautali.Monga kuwotcherera nduna, kuwotcherera kwa loboti kumatha kugwiritsidwa ntchito, komwe kumatha kupulumutsa ntchito zambiri ndikuwongolera magwiridwe antchito komanso kuwotcherera.

9. Chithandizo chapamwamba.Chithandizo chapamwamba chimaphatikizapo filimu ya phosphating, electroplating multicolored zinki, chromate, utoto wophika, okosijeni, ndi zina zotero. Kanema wa Phosphating amagwiritsidwa ntchito ngati mapepala ozizira komanso mapepala a electrolytic, ndipo ntchito yake ndi yophimba pamwamba pa zinthuzo.Filimu yoteteza imagwiritsidwa ntchito poletsa okosijeni;chachiwiri ndikuwonjezera kumamatira kwa utoto wake wophika.Electroplating colorful zinc amagwiritsidwa ntchito pochiza mbale zozizira;chromate ndi makutidwe ndi okosijeni nthawi zambiri amagwiritsidwa ntchito pochiza mbale za aluminiyamu ndi mbiri ya aluminiyamu;ake enieni pamwamba Kusankha njira processing zimatsimikiziridwa malinga ndi zofuna za kasitomala.

10. Msonkhano.Zomwe zimatchedwa msonkhano ndi kusonkhanitsa zigawo zingapo kapena zigawo zambiri pamodzi mwanjira inayake kuti zikhale chinthu chathunthu.Chimodzi mwa zinthu zomwe muyenera kuziganizira ndikutetezedwa kwa zinthu, osati zokanda ndi tokhala.Msonkhano ndi sitepe yomaliza pakumaliza kwa zinthu.Ngati zinthuzo sizingagwiritsidwe ntchito chifukwa cha zikwapu ndi zipolopolo, ziyenera kukonzedwanso ndi kukonzanso, zomwe zidzawononga nthawi yambiri yokonza ndikuwonjezera Mtengo wa chinthucho.Choncho, chidwi chapadera chiyenera kuperekedwa ku chitetezo cha chinthucho.

Nthawi yotumiza: Nov-29-2022